Have a complex or complicated problem? Perfect.

As an agile one-stop shop that knows metal better than anyone else, we push ourselves—each and every day—to create innovative, cost-effective solutions.

As an agile one-stop shop that knows metal better than anyone else, we push ourselves—each and every day—to create innovative, cost-effective solutions.

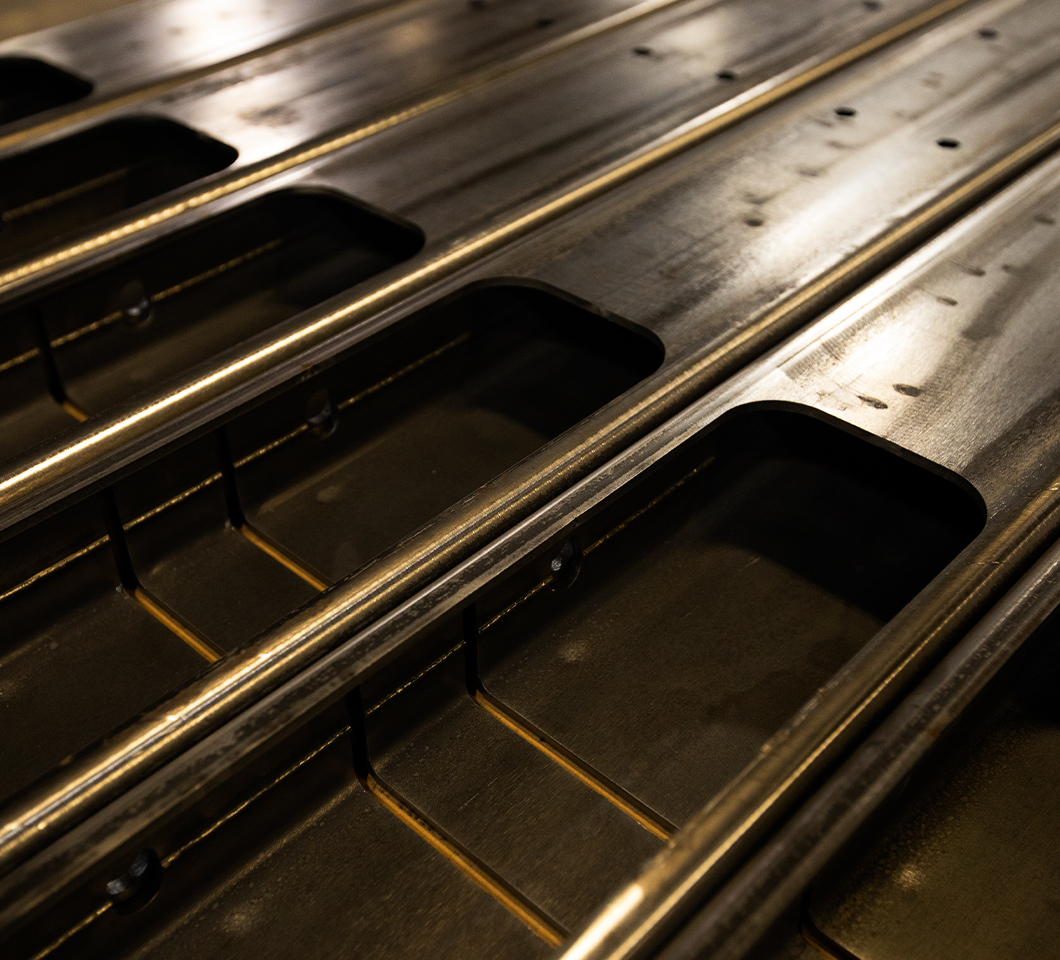

When it comes to complex stamping, fabrication and assembly, there’s no room for half-hearted efforts. To transform difficult problems into comprehensive solutions, you have to step up to whatever challenges lie ahead. After all, nothing worth doing comes easy.

We partner with you to concept and design a full service solution, from ideation and engineering to manufacturing, welding, and powder coating. Until the moment it leaves our doors, our team puts everything on the line to fully understand your needs to get the job done.